HIU-Newsletter

You a scientist yourself? A journalist, a political decision-maker or business representative? In our newsletters we compile the latest battery research news for you. Specially tailored to your personal area of interest.

The group “Beyond Li-Batteries: materials & interphases” developed sustainable materials for beyond Li-batteries (sodium and potassium-based batteries). The electrode-electrolyte interphase chemistry and morphology are investigated to understand the degradation mechanisms and enhance the electrochemical performance.

Lithium demand has significantly risen in the last years as lithium-ion batteries (LIBs) are used for powering portable electronics and electric vehicles owing to their high energy density. However, the lithium supply is mainly controlled by four companies with localized reserves, and hence the lithium price has continuously increased. In addition, concerns about the long-term availability and cost of the critical raw materials used in lithium-based battery production, e.g., cobalt, lithium, natural graphite, and copper, have been raised. Under this scenario, it is required to develop new battery technologies that can complement LIBs, such as sodium-ion (SIB) and potassium-ion batteries (PIBs). However, the performances beyond Li-batteries should be enhanced to become competitive technologies. The group is focused on developing novel, sustainable, and cost-effective cathode and anode electrode materials, as well as polymer-based electrolytes for sodium and potassium-ion batteries. Understanding the interphase formation mechanism allows us to implement different strategies to overcome the limitations of the state-of-the-art SIBs and PIBs.

Sodium-based batteries

Sodium-ion batteries (SIBs) have been postulated as potential low-cost energy storage devices for large-scale stationary applications and light electromobility due to the almost infinite and widely distributed sodium resources. Indeed, sodium-based electrode materials are composed of non-critical raw materials such as manganese, iron, or hard carbon, making SIBs sustainable. However, the electrochemical performance of SIBs must be further improved through specific strategies that optimize the cathode and anode active materials in terms of energy density and long-term cycling in line with maintaining their environmental competitiveness, as well as designing novel and advanced liquid and solid electrolytes able to stabilize the electrode-electrolyte interphase.

The current activities of the group in this field are:

- Bio-waste derived hard carbon anode materials through sustainable synthetic route

- Hybrid layered oxide cathode materials for high energy density sodium batteries

- Aqueous-based electrode processing

- Ternary and single-ion polymer electrolytes

- NASICON-type inorganic ceramic electrolytes

- Surface engineering of aluminum for anode-less sodium batteries

Potassium-ion batteries

Potassium-ion batteries (PIBs) have attracted significant attention as a complement to lithium-ion and sodium-ion batteries because they possess theoretically superior energy and power densities than SIBs, considering their lower standard electrode potential and faster ion diffusion while maintaining material sustainability. However, PIB research is in its infancy; therefore, further advances are necessary for electrode and electrolyte design and understanding of the interfacial chemistry to enhance their performance, as well as manufacturing potassium full cells to enhance their viability. In this context, currently, the group is working on the following:

- Bio-waste derived had carbon anode materials to replace natural graphite, a critical raw material

- Development of potassium-based layered oxides

- Understand the degradation mechanism of potassium-ion batteries

- Fluorine-free potassium-ion conductor polymer electrolytes

- Study the electrode-electrolyte interphases by surface techniques

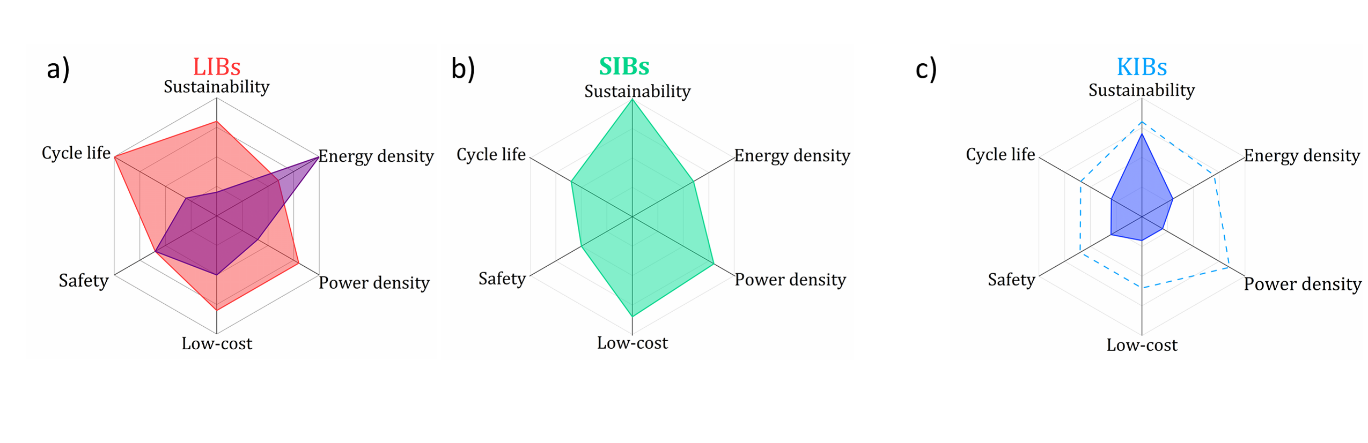

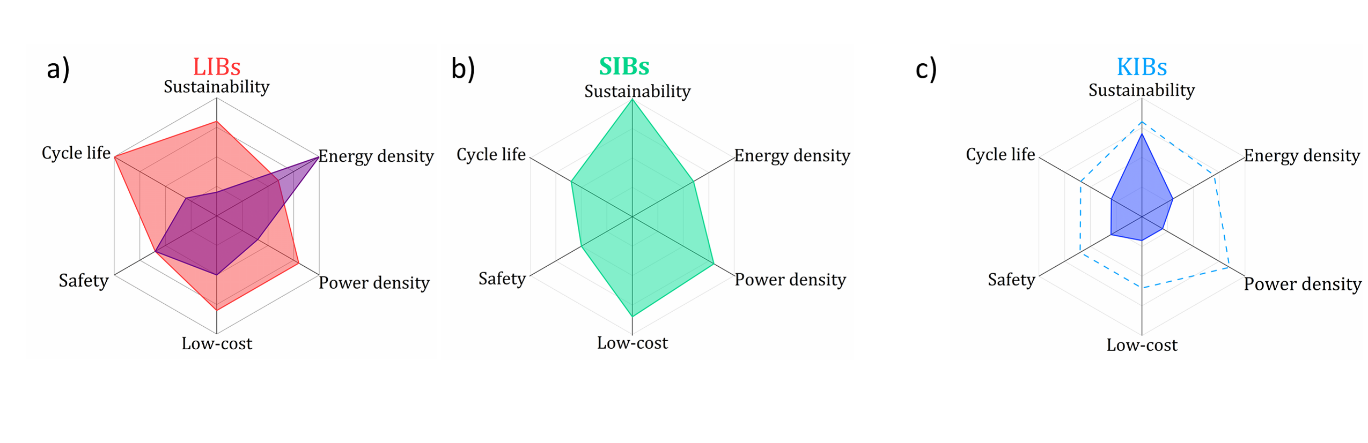

Radar plot of electrochemical, sustainability, and cost properties of the a) Lithium-ion (red: LFP-based and purple: NMC-based batteries), b) sodium-ion, and c) potassium-ion batteries (cyan dots: theoretical values and blue line: experimental values).

Electrode-electrolyte interphases

Typically, the electrolytes operate outside their electrochemical stability window to enhance the energy density of the batteries. Therefore, during the battery’s first cycles, the electrolyte is reduced /oxidized, forming a passivation layer on the surface of the electrodes called solid electrolyte interphase on the anode and cathode electrolyte interphase on the cathode side. The electrode-electrolyte interphases’ play a crucial role in the safety, metal deposition, power capability, Coulombic efficiency, irreversible capacity, and cycle life of the batteries. Therefore, understanding, not only in terms of properties but also formation mechanism, is crucial to develop competitive batteries. However, the knowledge of beyond-lithium battery interfaces and interphases is still limited. The group is carrying out the following activities:

- Investigate the chemistry of the electrode-electrolyte interphase upon electrochemical cycling (lithium-metal, sodium- and potassium-based batteries)

- Depth profiling of the electrode-electrolyte interphases to understand the degradation mechanism of the electrolytes

- Study the interphases formed in solid-solid material, i.e., electrode-solid electrolytes

- Improve the initial reversibility of the materials by modifying the formed electrode-electrolyte interphase.

Sodium-based batteries

Sodium-ion batteries (SIBs) have been postulated as potential low-cost energy storage devices for large-scale stationary applications and light electromobility due to the almost infinite and widely distributed sodium resources. Indeed, sodium-based electrode materials are composed of non-critical raw materials such as manganese, iron, or hard carbon, making SIBs sustainable. However, the electrochemical performance of SIBs must be further improved through specific strategies that optimize the cathode and anode active materials in terms of energy density and long-term cycling in line with maintaining their environmental competitiveness, as well as designing novel and advanced liquid and solid electrolytes able to stabilize the electrode-electrolyte interphase.

The current activities of the group in this field are:

- Bio-waste derived hard carbon anode materials through sustainable synthetic route

- Hybrid layered oxide cathode materials for high energy density sodium batteries

- Aqueous-based electrode processing

- Ternary and single-ion polymer electrolytes

- NASICON-type inorganic ceramic electrolytes

- Surface engineering of aluminum for anode-less sodium batteries

Potassium-ion batteries

Potassium-ion batteries (PIBs) have attracted significant attention as a complement to lithium-ion and sodium-ion batteries because they possess theoretically superior energy and power densities than SIBs, considering their lower standard electrode potential and faster ion diffusion while maintaining material sustainability. However, PIB research is in its infancy; therefore, further advances are necessary for electrode and electrolyte design and understanding of the interfacial chemistry to enhance their performance, as well as manufacturing potassium full cells to enhance their viability. In this context, currently, the group is working on the following:

- Bio-waste derived had carbon anode materials to replace natural graphite, a critical raw material

- Development of potassium-based layered oxides

- Understand the degradation mechanism of potassium-ion batteries

- Fluorine-free potassium-ion conductor polymer electrolytes

- Study the electrode-electrolyte interphases by surface techniques

Radar plot of electrochemical, sustainability, and cost properties of the a) Lithium-ion (red: LFP-based and purple: NMC-based batteries), b) sodium-ion, and c) potassium-ion batteries (cyan dots: theoretical values and blue line: experimental values).

Electrode-electrolyte interphases

Typically, the electrolytes operate outside their electrochemical stability window to enhance the energy density of the batteries. Therefore, during the battery’s first cycles, the electrolyte is reduced /oxidized, forming a passivation layer on the surface of the electrodes called solid electrolyte interphase on the anode and cathode electrolyte interphase on the cathode side. The electrode-electrolyte interphases’ play a crucial role in the safety, metal deposition, power capability, Coulombic efficiency, irreversible capacity, and cycle life of the batteries. Therefore, understanding, not only in terms of properties but also formation mechanism, is crucial to develop competitive batteries. However, the knowledge of beyond-lithium battery interfaces and interphases is still limited. The group is carrying out the following activities:

- Investigate the chemistry of the electrode-electrolyte interphase upon electrochemical cycling (lithium-metal, sodium- and potassium-based batteries)

- Depth profiling of the electrode-electrolyte interphases to understand the degradation mechanism of the electrolytes

- Study the interphases formed in solid-solid material, i.e., electrode-solid electrolytes

- Improve the initial reversibility of the materials by modifying the formed electrode-electrolyte interphase.The “Beyond Li-Batteries: materials & interphases” group belongs to the echem1 main group with access to the flowing devices:

– Inorganic and organic chemistry labs, including glove boxes, planetary ball miller, microwave reactor

– Oven lab, including muffle and tubular furnaces

– 25 sq. m Dry room, composed of UV chamber, hot press,

– Battery cyclers

– Potentiostats

– Impedance analyzers

– Pycnometer and density meter

– BET Surface Area Analysis with different gases

– Thermogravimetric analysis coupled with a mass spectrometer and differential scanning calorimeter

– FTIR/Raman with the possibility of running operando experiments

– X-ray diffractometer for ex-situ and in-situ experiments

– X-ray photoelectron spectroscopy

MSc. Aditya Khadilkar

Dr. Zahilia Caban Huertas (Postdoc Marie Curie Fellowship)

Dr. Daniel Roscher (daniel.kroetschel@kit.edu)

SIMBA

Sodium-Ion and sodium Metal Batteries for efficient and sustainable next-generation energy storage (2021-2024)

The SIMBA European project comprises 15 partners and aims to develop a highly cost-effective, safe, all-solid-state sodium-ion and sodium-metal battery for stationary storage applications. Sodium-ion batteries are similar to lithium-ion batteries; however, several scientific and technical challenges must be addressed in understanding electrochemical processes and degradation mechanisms, electrode, solid-state electrolyte, and cell manufacturing. The SIMBA project aims to solve these challenges and pave the way to market introduction. The work at the HIU focuses on developing a new class of single-ion conductive polymer electrolyte with wide electrochemical stability window and high ionic conductivity at room temperature for all-solid-state sodium-ion batteries. In addition, HIU will perform the Life Cycle Assessment (LCA) of the SIMBA battery.

Partners:

– Technische Universität Darmstadt (TUDa)

– Uppsala University (UU)

– University of Birmingham (UBham)

– University of Warwick – Warwick Manufacturing Group (WMG)

– Commissariat à l’énergie atomique et aux énergie alternatives (CEA)

– Institute for Energy Technology (IFE)

– Slovak Academy of Science (SAS)

– Fraunhofer-Institut für Solare Energiesysteme ISE (FHG)

– Elkem ASA (Elkem)

– Yunasko-Ukranie LLC (YUN)

– Saft Groupe S.A. (SAFT)

– Altris AB (Altris)

– TES-Recupyl SAS (Recupyl)

– Uniresearch B.V. (UNR)

Further information:

SPIRIT

Solid-state Potassium-Ion batteries for safe and sustainable energy storage (2022-2025)

SPIRIT collaborative project is part of the M-ERA.net 2021 call, funded by BMBF, with Spanish, German, and Israeli academic and industrial partners. The aim of SPIRIT is to develop a safe, sustainable, and cost-competitive solid-state potassium-ion battery for large-scale stationary applications and light electromobility, with energy densities comparable to current lithium-ion batteries and competitive with sodium-ion Batteries. The HIU’s main goals are to design and develop novel, low-cost, scalable, and safe potassium-ion conductive ternary polymer electrolytes, synthesize long-term and high energy bio-waste derived hard carbon anode materials, understand the electrolyte-electrode degradation and interfacial formation and manufactured solid-state potassium-ion demonstrators.

Partners:

– Universidad Complutense de Madrid (UCM)

– Institute of Polymer Science and Technology (CSIC)

– Weizmann Institute of Science (WIS)

– Io-li-tec – Ionic Liquids Technologies GmbH (IOL)

Further information:

https://www.spirit-k-ion.com/

Transition transfer

Sodium-ion materials and demonstrators for mobile and stationary energy storage systems (2023-2026)

Transition transfer is a collaborative research project with German partners funded by BMBF. The overall goal is to develop high-performance, cost-effective, and environmentally friendly sodium demonstrations using two different families of electrolytes. The Transition Transfer project follows on from the investigations and activities of the TRANSITION project, with the precise aim of bringing the processes to a higher technical level (TRL6 for liquid electrolyte and TRL4 for polymer electrolyte and anode-less system). HIU activities are preparation, optimization, and up-scaling of bio-waste-derived hard carbon anode materials, as well as manufacturing hard carbon electrodes, synthesis and optimization of sodium polymer electrolytes, and development of polymer electrolytes based anode-less sodium demonstrator.

Partners:

– Zentrum für Sonnenenergie- und Wasserstoff-Forschung Baden-Württemberg (ZSW)

– Humboldt-Universität zu Berlin (HUB)

– Friedrich-Schiller-Universität Jena (FSU)

eNargiZinc

Towards innovative and affordable sodium- and zinc-based energy storage systems based on more sustainable and locally-sourced materials (2024-2026)

The eNargiZinc is a Marie Sklodowska-Curie Actions Doctoral Network project, which aims to train creative, entrepreneurial, innovative, and resilient doctoral candidates in academic and non-academic sectors, able to face current and future challenges and to convert knowledge and ideas into products and services for economic and social benefit. eNargiZinc aims at developing new knowledge, technology, and commercially exploitable products related to innovative and affordable next-generation electrochemical energy devices, such as sodium-ion batteries, zinc-ion batteries, zinc-air batteries, and zinc-ion hybrid supercapacitors, targeting long-term sustainability through the use of abundant and renewable materials and low environmental-impact production processes.

Partners:

– Universidad de Zaragoza (UNIZAR)

– Consorzio Interuniversitario Nazionale per la Scienza e Tecnologia dei Materiali (ISTM)

– Imperial College London (ICL)

– Deregallera Limited

– Fundación IMDEA Energía (IME)

– CIC ENERGIGUNE (CICE)

– The University of Warwick (WMG)

– VARTA Miccrobattery GmbH (VARTA)

– GAZ Geräte-und Akkumulatorrenwerk Zwickau GmbH (GAZ)

4NIB – 4 Volt Sodium-Ion Battery (2023-2026)

The aim of the “4NIB” project is to develop and optimize bio-waste derived hard carbon anode (HIU/KIT), polyanion phosphate cathode (ZSW and FZJ) and electrolyte (ALU) and to manufacture an innovative high-performance cost-effective and environmentally friendly sodium-ion battery (ZSW) for mobile (scooter, light-duty and city-transportation vehicles) and stationary applications. The final goal is to demonstrate a sodium pouch-cell (TRL4) with a specific energy of ≥ 200 Wh/kg at the stack level. The implementation of a proof of concept and the development of the full sodium-ion battery cell demonstrators is based on successfully completed preliminary research at the material level (anode, cathode and electrolyte) by each project partner.

Partners:

– Zentrum für Sonnenergie- und Wasserstoff-Forschung (ZSW) – coordinator;

– Albert Ludwigs Universität Freiburg (ALU)

– Forschungszentrum Jülich GmbH (FZJ).

Sodium-based batteries

Sodium-ion batteries (SIBs) have been postulated as potential low-cost energy storage devices for large-scale stationary applications and light electromobility due to the almost infinite and widely distributed sodium resources. Indeed, sodium-based electrode materials are composed of non-critical raw materials such as manganese, iron, or hard carbon, making SIBs sustainable. However, the electrochemical performance of SIBs must be further improved through specific strategies that optimize the cathode and anode active materials in terms of energy density and long-term cycling in line with maintaining their environmental competitiveness, as well as designing novel and advanced liquid and solid electrolytes able to stabilize the electrode-electrolyte interphase.

The current activities of the group in this field are:

- Bio-waste derived hard carbon anode materials through sustainable synthetic route

- Hybrid layered oxide cathode materials for high energy density sodium batteries

- Aqueous-based electrode processing

- Ternary and single-ion polymer electrolytes

- NASICON-type inorganic ceramic electrolytes

- Surface engineering of aluminum for anode-less sodium batteries

Potassium-ion batteries

Potassium-ion batteries (PIBs) have attracted significant attention as a complement to lithium-ion and sodium-ion batteries because they possess theoretically superior energy and power densities than SIBs, considering their lower standard electrode potential and faster ion diffusion while maintaining material sustainability. However, PIB research is in its infancy; therefore, further advances are necessary for electrode and electrolyte design and understanding of the interfacial chemistry to enhance their performance, as well as manufacturing potassium full cells to enhance their viability. In this context, currently, the group is working on the following:

- Bio-waste derived had carbon anode materials to replace natural graphite, a critical raw material

- Development of potassium-based layered oxides

- Understand the degradation mechanism of potassium-ion batteries

- Fluorine-free potassium-ion conductor polymer electrolytes

- Study the electrode-electrolyte interphases by surface techniques

Radar plot of electrochemical, sustainability, and cost properties of the a) Lithium-ion (red: LFP-based and purple: NMC-based batteries), b) sodium-ion, and c) potassium-ion batteries (cyan dots: theoretical values and blue line: experimental values).

Electrode-electrolyte interphases

Typically, the electrolytes operate outside their electrochemical stability window to enhance the energy density of the batteries. Therefore, during the battery’s first cycles, the electrolyte is reduced /oxidized, forming a passivation layer on the surface of the electrodes called solid electrolyte interphase on the anode and cathode electrolyte interphase on the cathode side. The electrode-electrolyte interphases’ play a crucial role in the safety, metal deposition, power capability, Coulombic efficiency, irreversible capacity, and cycle life of the batteries. Therefore, understanding, not only in terms of properties but also formation mechanism, is crucial to develop competitive batteries. However, the knowledge of beyond-lithium battery interfaces and interphases is still limited. The group is carrying out the following activities:

- Investigate the chemistry of the electrode-electrolyte interphase upon electrochemical cycling (lithium-metal, sodium- and potassium-based batteries)

- Depth profiling of the electrode-electrolyte interphases to understand the degradation mechanism of the electrolytes

- Study the interphases formed in solid-solid material, i.e., electrode-solid electrolytes

- Improve the initial reversibility of the materials by modifying the formed electrode-electrolyte interphase.

Sodium-based batteries

Sodium-ion batteries (SIBs) have been postulated as potential low-cost energy storage devices for large-scale stationary applications and light electromobility due to the almost infinite and widely distributed sodium resources. Indeed, sodium-based electrode materials are composed of non-critical raw materials such as manganese, iron, or hard carbon, making SIBs sustainable. However, the electrochemical performance of SIBs must be further improved through specific strategies that optimize the cathode and anode active materials in terms of energy density and long-term cycling in line with maintaining their environmental competitiveness, as well as designing novel and advanced liquid and solid electrolytes able to stabilize the electrode-electrolyte interphase.

The current activities of the group in this field are:

- Bio-waste derived hard carbon anode materials through sustainable synthetic route

- Hybrid layered oxide cathode materials for high energy density sodium batteries

- Aqueous-based electrode processing

- Ternary and single-ion polymer electrolytes

- NASICON-type inorganic ceramic electrolytes

- Surface engineering of aluminum for anode-less sodium batteries

Potassium-ion batteries

Potassium-ion batteries (PIBs) have attracted significant attention as a complement to lithium-ion and sodium-ion batteries because they possess theoretically superior energy and power densities than SIBs, considering their lower standard electrode potential and faster ion diffusion while maintaining material sustainability. However, PIB research is in its infancy; therefore, further advances are necessary for electrode and electrolyte design and understanding of the interfacial chemistry to enhance their performance, as well as manufacturing potassium full cells to enhance their viability. In this context, currently, the group is working on the following:

- Bio-waste derived had carbon anode materials to replace natural graphite, a critical raw material

- Development of potassium-based layered oxides

- Understand the degradation mechanism of potassium-ion batteries

- Fluorine-free potassium-ion conductor polymer electrolytes

- Study the electrode-electrolyte interphases by surface techniques

Radar plot of electrochemical, sustainability, and cost properties of the a) Lithium-ion (red: LFP-based and purple: NMC-based batteries), b) sodium-ion, and c) potassium-ion batteries (cyan dots: theoretical values and blue line: experimental values).

Electrode-electrolyte interphases

Typically, the electrolytes operate outside their electrochemical stability window to enhance the energy density of the batteries. Therefore, during the battery’s first cycles, the electrolyte is reduced /oxidized, forming a passivation layer on the surface of the electrodes called solid electrolyte interphase on the anode and cathode electrolyte interphase on the cathode side. The electrode-electrolyte interphases’ play a crucial role in the safety, metal deposition, power capability, Coulombic efficiency, irreversible capacity, and cycle life of the batteries. Therefore, understanding, not only in terms of properties but also formation mechanism, is crucial to develop competitive batteries. However, the knowledge of beyond-lithium battery interfaces and interphases is still limited. The group is carrying out the following activities:

- Investigate the chemistry of the electrode-electrolyte interphase upon electrochemical cycling (lithium-metal, sodium- and potassium-based batteries)

- Depth profiling of the electrode-electrolyte interphases to understand the degradation mechanism of the electrolytes

- Study the interphases formed in solid-solid material, i.e., electrode-solid electrolytes

- Improve the initial reversibility of the materials by modifying the formed electrode-electrolyte interphase.The “Beyond Li-Batteries: materials & interphases” group belongs to the echem1 main group with access to the flowing devices:

– Inorganic and organic chemistry labs, including glove boxes, planetary ball miller, microwave reactor

– Oven lab, including muffle and tubular furnaces

– 25 sq. m Dry room, composed of UV chamber, hot press,

– Battery cyclers

– Potentiostats

– Impedance analyzers

– Pycnometer and density meter

– BET Surface Area Analysis with different gases

– Thermogravimetric analysis coupled with a mass spectrometer and differential scanning calorimeter

– FTIR/Raman with the possibility of running operando experiments

– X-ray diffractometer for ex-situ and in-situ experiments

– X-ray photoelectron spectroscopy

SIMBA

Sodium-Ion and sodium Metal Batteries for efficient and sustainable next-generation energy storage (2021-2024)

The SIMBA European project comprises 15 partners and aims to develop a highly cost-effective, safe, all-solid-state sodium-ion and sodium-metal battery for stationary storage applications. Sodium-ion batteries are similar to lithium-ion batteries; however, several scientific and technical challenges must be addressed in understanding electrochemical processes and degradation mechanisms, electrode, solid-state electrolyte, and cell manufacturing. The SIMBA project aims to solve these challenges and pave the way to market introduction. The work at the HIU focuses on developing a new class of single-ion conductive polymer electrolyte with wide electrochemical stability window and high ionic conductivity at room temperature for all-solid-state sodium-ion batteries. In addition, HIU will perform the Life Cycle Assessment (LCA) of the SIMBA battery.

Partners:

– Technische Universität Darmstadt (TUDa)

– Uppsala University (UU)

– University of Birmingham (UBham)

– University of Warwick – Warwick Manufacturing Group (WMG)

– Commissariat à l’énergie atomique et aux énergie alternatives (CEA)

– Institute for Energy Technology (IFE)

– Slovak Academy of Science (SAS)

– Fraunhofer-Institut für Solare Energiesysteme ISE (FHG)

– Elkem ASA (Elkem)

– Yunasko-Ukranie LLC (YUN)

– Saft Groupe S.A. (SAFT)

– Altris AB (Altris)

– TES-Recupyl SAS (Recupyl)

– Uniresearch B.V. (UNR)

Further information:

SPIRIT

Solid-state Potassium-Ion batteries for safe and sustainable energy storage (2022-2025)

SPIRIT collaborative project is part of the M-ERA.net 2021 call, funded by BMBF, with Spanish, German, and Israeli academic and industrial partners. The aim of SPIRIT is to develop a safe, sustainable, and cost-competitive solid-state potassium-ion battery for large-scale stationary applications and light electromobility, with energy densities comparable to current lithium-ion batteries and competitive with sodium-ion Batteries. The HIU’s main goals are to design and develop novel, low-cost, scalable, and safe potassium-ion conductive ternary polymer electrolytes, synthesize long-term and high energy bio-waste derived hard carbon anode materials, understand the electrolyte-electrode degradation and interfacial formation and manufactured solid-state potassium-ion demonstrators.

Partners:

– Universidad Complutense de Madrid (UCM)

– Institute of Polymer Science and Technology (CSIC)

– Weizmann Institute of Science (WIS)

– Io-li-tec – Ionic Liquids Technologies GmbH (IOL)

Further information:

https://www.spirit-k-ion.com/

Transition transfer

Sodium-ion materials and demonstrators for mobile and stationary energy storage systems (2023-2026)

Transition transfer is a collaborative research project with German partners funded by BMBF. The overall goal is to develop high-performance, cost-effective, and environmentally friendly sodium demonstrations using two different families of electrolytes. The Transition Transfer project follows on from the investigations and activities of the TRANSITION project, with the precise aim of bringing the processes to a higher technical level (TRL6 for liquid electrolyte and TRL4 for polymer electrolyte and anode-less system). HIU activities are preparation, optimization, and up-scaling of bio-waste-derived hard carbon anode materials, as well as manufacturing hard carbon electrodes, synthesis and optimization of sodium polymer electrolytes, and development of polymer electrolytes based anode-less sodium demonstrator.

Partners:

– Zentrum für Sonnenenergie- und Wasserstoff-Forschung Baden-Württemberg (ZSW)

– Humboldt-Universität zu Berlin (HUB)

– Friedrich-Schiller-Universität Jena (FSU)

eNargiZinc

Towards innovative and affordable sodium- and zinc-based energy storage systems based on more sustainable and locally-sourced materials (2024-2026)

The eNargiZinc is a Marie Sklodowska-Curie Actions Doctoral Network project, which aims to train creative, entrepreneurial, innovative, and resilient doctoral candidates in academic and non-academic sectors, able to face current and future challenges and to convert knowledge and ideas into products and services for economic and social benefit. eNargiZinc aims at developing new knowledge, technology, and commercially exploitable products related to innovative and affordable next-generation electrochemical energy devices, such as sodium-ion batteries, zinc-ion batteries, zinc-air batteries, and zinc-ion hybrid supercapacitors, targeting long-term sustainability through the use of abundant and renewable materials and low environmental-impact production processes.

Partners:

– Universidad de Zaragoza (UNIZAR)

– Consorzio Interuniversitario Nazionale per la Scienza e Tecnologia dei Materiali (ISTM)

– Imperial College London (ICL)

– Deregallera Limited

– Fundación IMDEA Energía (IME)

– CIC ENERGIGUNE (CICE)

– The University of Warwick (WMG)

– VARTA Miccrobattery GmbH (VARTA)

– GAZ Geräte-und Akkumulatorrenwerk Zwickau GmbH (GAZ)

4NIB – 4 Volt Sodium-Ion Battery (2023-2026)

The aim of the “4NIB” project is to develop and optimize bio-waste derived hard carbon anode (HIU/KIT), polyanion phosphate cathode (ZSW and FZJ) and electrolyte (ALU) and to manufacture an innovative high-performance cost-effective and environmentally friendly sodium-ion battery (ZSW) for mobile (scooter, light-duty and city-transportation vehicles) and stationary applications. The final goal is to demonstrate a sodium pouch-cell (TRL4) with a specific energy of ≥ 200 Wh/kg at the stack level. The implementation of a proof of concept and the development of the full sodium-ion battery cell demonstrators is based on successfully completed preliminary research at the material level (anode, cathode and electrolyte) by each project partner.

Partners:

– Zentrum für Sonnenergie- und Wasserstoff-Forschung (ZSW) – coordinator;

– Albert Ludwigs Universität Freiburg (ALU)

– Forschungszentrum Jülich GmbH (FZJ).

Dr. Maider Zarrabeitia Beyond Li-Batteries: Materials & Interphases Tel: +49 (0731) 50 34111 Mail: maider.ipina(at)kit.edu

Dr. Maider Zarrabeitia Beyond Li-Batteries: Materials & Interphases Tel: +49 (0731) 50 34111 Mail: maider.ipina(at)kit.edu ORCID: 0000-0003-1305-2136

Scopus Author ID: 56533588600

You a scientist yourself? A journalist, a political decision-maker or business representative? In our newsletters we compile the latest battery research news for you. Specially tailored to your personal area of interest.

Helmholtz Institute Ulm Electrochemical energy storage (HIU)

Helmholtzstraße 11

89081 Ulm

Germany

Tel.: +49 0731 5034001

Fax: +49 (0731) 50 34009