November 22nd, 2023

On November 22nd, a delegation from the Swedish battery and cell manufacturer Northvolt visited the Helmholtz Institute in Ulm. In addition to battery construction, Northvolt has also been operating its own cell production for several years and is now building another cell production plant in Heide (Dithmarschen) in northern Germany. The capacity of the first German plant should be around 60 GWh at full production one day and be enough to power one million vehicles.

The Northvolt delegation’s visit primarily served to establish further contacts with battery research in Ulm. Common topics included future, innovative cell chemistries for battery cells, the training of specialists for the battery sector, processes in cell production and the European economic location for battery production.

Welcome to HIU, @northvolt! ?? 1 day after Northvolt's announcement to soon produce #sodium-ion #batteries a NV delegation visited our institute in Ulm. Lots of intense talks, great getting to know you! @MaxFichtner @ClusterPolis @CELEST_18 @uni_ulm @DLR_Energie @KITKarlsruhe pic.twitter.com/D87Vx2X6Xd

— Helmholtz Institute Ulm ? (@HelmholtzUlm) November 23, 2023

As a manufacturer of lithium-ion cells, Northvolt focuses on applications in electric cars and stationary energy storage systems.

The cell manufacturer recently announced that it would now also develop sodium-ion batteries. The manufacturer announced a sodium cell that is said to be produced more cost-effectively and sustainably than the sodium-ion cells from Asia that are common today. The cell chemistry is developed at Northvolt Labs, in Västerås in Sweden. Northvolt stated in a press release that it had initially designed its own sodium-ion batteries only for stationary applications and not yet for electromobility.

Links: https://northvolt.com/products/cells/sodium-ion/

October 4th, 2023

Polymer electrolytes have a long history in battery research. Both material development and our fundamental understanding of ion transport mechanisms in polymers have evolved with it. Today we are at a crossroads where researchers see many possible paths into the future of batteries – and have a variety of battery technologies to choose from. Diversification in many different cell chemistries opens up new avenues to explore. Experts encourage us to completely rethink some concepts and findings from days gone by.

This week our colleagues, Sergio Rodríguez, María Martínez & Maica Morant together with Prof. Armand, took part in #ESPE23 – 1st European Symposium on #Polymer #Electrolytes for #Battery Applications of the @ClusterPolis, at @KITKarlsruhe.

?Thanks for the valuable contributions! pic.twitter.com/nKU8K0LQfT— CIC energiGUNE (@energigune_brta) September 29, 2023

During the first European Symposium on Polymer Electrolytes for Battery Applications (ESPE23), which took place from September 25th to 27th, 2023 at the Karlsruhe Institute of Technology, more than 100 participants from all over Europe came together to present their latest results and network.

The program included 30 lectures as well as a poster session, several networking sessions and a symposium dinner. Bing-Xuan Shi, a doctoral student at the Justus Liebig University in Gießen, was awarded the poster prize provided by rhd instruments GmbH & Co. KG for his outstanding research work, which he presented at the symposium.

Links:

https://www.postlithiumstorage.org/de/news-events/detailseite/1st-european-symposium-on-polymer-electrolytes-for-battery-applications

https://www.postlithiumstorage.org/en/espe23

In the seminar at the Helmholtz Institute Ulm (HIU), outstanding international battery researchers share their scientific findings and technological inventions with Ulm scientists and students. The seminar takes place every Tuesday at 2:00 p.m. during the lecture period.

06.10.2023

Prof. Dr. Alejandro A. Franco

Laboratoire de Réactivité et Chimie des Solides (LRCS), Univ. de Picardie Jules Verne, Amiens, France

05.12.2023

Dr. Laurent Zinck

Innolith Science and Technology GmbH

September 16th, 2023

HIU director Professor Maximilian Fichtner was awarded the “Ulmer Köpfchen” this year. The “Ulmer Köpfchen” honors people who have achieved something special for society through their work. Fichtner was honored as a researcher for his work on the “battery of the future”.

Gülay Kul & our director @MaxFichtner were awarded with the “Ulm Köpfchen” 2023. Gülay Kul is spokesperson for the #Ulm Women’s Forum. Kul & Fichtner have committed themselves to social issues in Ulm & were therefore selected from several candidates. https://t.co/JhryYJhPBc pic.twitter.com/ahEW75BHsr

— Helmholtz Institute Ulm ? (@HelmholtzUlm) September 18, 2023

In addition to Maximilian Fichtner, Gülay Kul, integration manager in the Biberach district, also received the award for her work this year. This year’s specially assembled search committee included, among others, Neu-Ulm’s mayor Katrin Albsteiger and Ulm’s mayor Iris Mann.

The “Ulmer Köpfchen” goes back to the Ulm master goldsmith Wolf-Peter Schwarz, who had already made and sold individual heads in the 1990s. In 2020, he wanted to give his little heads a contemporary meaning – as a sign of community and cohesion.

Those people should be honored “who do or say things far away from the loud mainstream that no one would have expected of them,” says the website. What is crucial, however, is that it pursues a social or community goal.

Links:

https://www.zukunft-mit-koepfchen.de/ulmer-koepfchen-2023/

https://www.schwaebische.de/regional/ulm-alb-donau/ulm/warum-dieser-ulmer-batterieforscher-mit-koepfchen-geehrt-wird-1900356

https://www.augsburger-allgemeine.de/neu-ulm/ulm-ulmer-professor-macht-batterieforschung-fuer-alle-verstaendlich-id67777311.html

July 11-12, 2023

This year, the closed conference of the Helmholtz Institute Ulm took place on the premises of the POLiS Cluster of Excellence (LM16). A former production hall of Daimler AG served as the venue. The researchers at the HIU exchanged views on all current and relevant topics of electrochemical energy storage at the two-day retreat. As always, the focus was on the material properties for future, innovative battery cells.

Download: Program HIU Biennial Meeting 2023

Download: Scienfic Posters List

Lots of great talks by our PIs and scientists at our 12th Biennial Meeting in #Ulm #Science Park II @uni_ulm @ClusterPolis @KITKarlsruhe @DLR_de @DLR_en @CELEST_18 @MaxFichtner @ervinguru @SFleischmann_ @CPunckt pic.twitter.com/OV8k9VO9U4

— Helmholtz Institute Ulm ???? (@HelmholtzUlm) July 11, 2023

The meeting started with the presentation of experimental “Methods and Techniques” for investigating battery materials. For this purpose, certain new analysis devices were presented, which have recently become available to the researchers at the HIU. The HIU researchers, employed through the German Aerospace Center (DLR), presented their research findings in the field of battery modelling.

Another subject area was filled exclusively with research lectures on lithium-ion batteries: The focus here was, for example, the prediction of battery aging and cell analysis, electrode coatings and the improvement of lithium intercalation kinetics. On the second day of the conference, cell chemistries beyond lithium-ion technology were presented and research on “mechanisms, interfaces and interphases” was presented.

Finally, the topics “solid-state batteries” and research on “sustainable materials and processes” found their place in the examination program.

Weitere Links:

http://www.hiu-batteries.de

27. Juni 2023

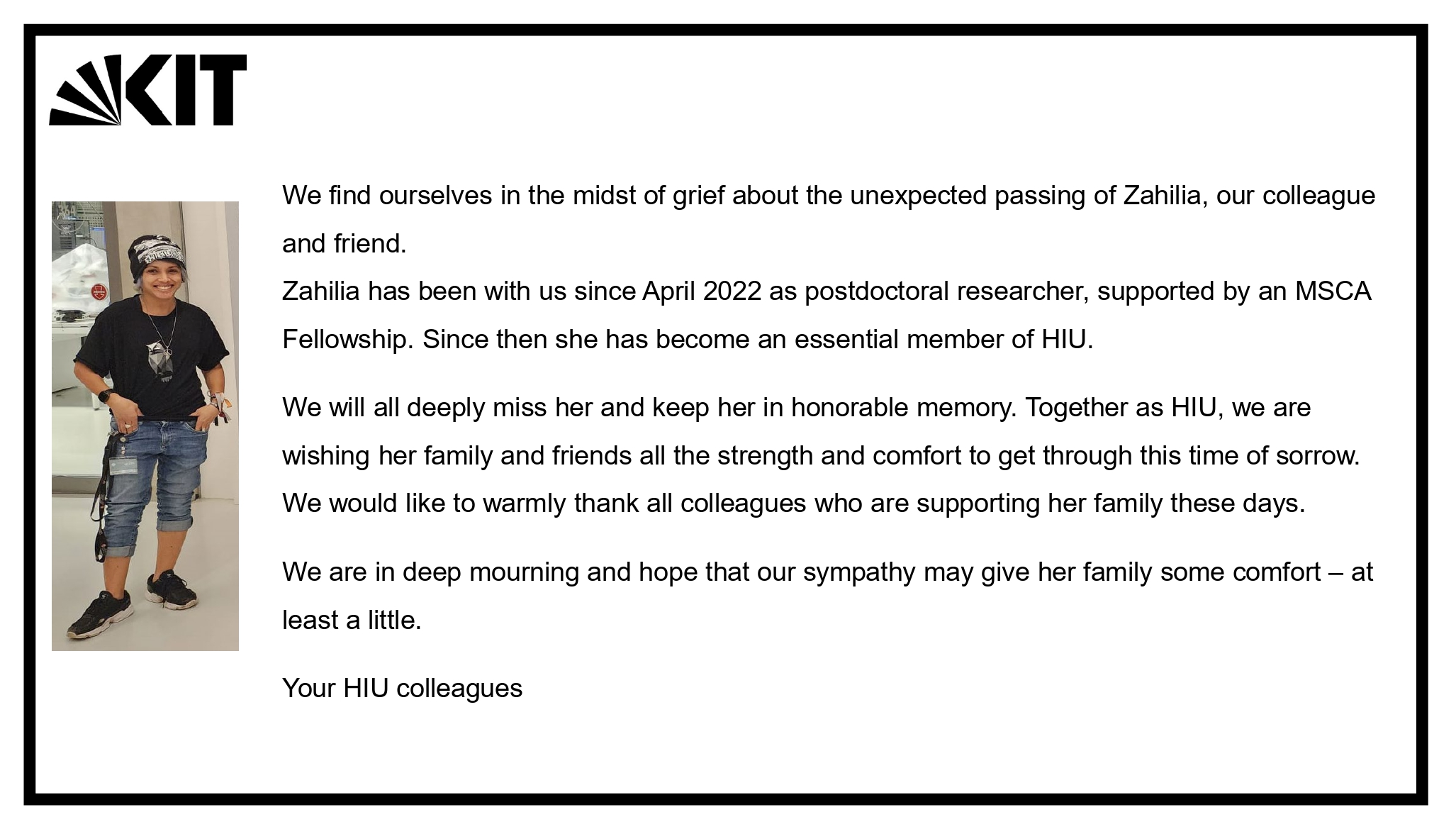

Dr. Zahilia Caban Huertas (✝ 22.06.2023, Ulm)

Dear all,

We find ourselves in the midst of grief about the unexpected passing of Zahilia, a valuable researcher, our colleague and friend.

Zahilia has been with us since April 2022 as postdoctoral researcher, supported by an MSCA Fellowship to investigate solid-state batteries. Since then she has become an essential member of our HIU family.

We will all deeply miss her and keep her in honorable memory. Zahilia and her family are in our thoughts and prayers. Together as HIU, we are wishing her family and friends all the strength and comfort to get through this time of sorrow. We have expressed our sincerest condolences to her sister and family on behalf of all colleagues at HIU, and would like to warmly thank all colleagues who are supporting her family these days.

We are in deep mourning and hope that our sympathy may give her family some comfort – at least a little.

On behalf of all HIU colleagues,

Dominic Bresser

Heribert Wilhelm

Maximilian Fichtner

June 5th, 2023

Two million euros for research on organic electrode materials: Professor Birgit Esser receives Consolidator Grant. The chemist Prof. Birgit Esser from the Institute for Organic Chemistry II and New Materials at the University of Ulm has received a Consolidator Grant from the European Research Council (ERC) of two million euros for five years for her project “NanOBatt”. The researcher is also an associated research group leader at the Helmholtz Institute Ulm (HIU). Organic electrode materials (OEM) for next-generation batteries are to be researched with NanOBatt. The focus will be on improving OEM porosity, thereby facilitating ion diffusion. OEM have many advantages: they consist of widely available elements, are accessible with a low carbon footprint and can be easily recycled. The ERC Consolidator Grant aims to strengthen outstanding scientists in expanding their working groups and promote international visibility.

Glückwunsch an Prof. Birgit Esser @Besserchemistry: Die Chemikerin der #uulm erhält einen Consolidator Grant des @ERC_Research in Höhe von 2 Mio. Euro! ?Im Projekt ?NanOBatt?erforscht sie organische Elektrodenmaterialien für Batterien. https://t.co/6sy5PZbVlm *cl/?Eberhardt pic.twitter.com/zwVcIOETzr

— Universität Ulm (@uni_ulm) June 5, 2023

Be it smartphones or electric cars, wireless headphones or robotic lawn mowers: batteries are in many electrical devices. And the demand for it keeps increasing. New energy storage solutions are needed. With her NanoBatt project, Prof. Birgit Esser wants to research a fundamentally new concept for organic electrode materials. The chemist combines the necessary expertise in organic synthesis chemistry with know-how from the field of organic battery electrode materials in a unique way. With its holistic approach, Esser wants to close the gap between basic research and the application of organic materials.

Improve porosity of organic materials

“Compared to inorganic materials for batteries, the field of OEMs has been significantly less researched,” says Esser. The problem: Existing OEMs have poor porosity, which impedes the diffusion of counterions to electroactive sites or makes redox processes, i.e. the simultaneous loss or acceptance of electrons, irreversible. This severely limits their performance and applicability. In order to improve the porosity of the organic materials, Esser relies on so-called redox-active, conjugated nanohoops with NanOBatt. These are hoop-shaped molecules whose electrons do not stay at a fixed point but move within the hoop. “That could be an advantage and stabilize the charge,” explains the chemist. The aim of NanOBatt is to produce such nanohoops, the synthesis of which is sometimes very complex. The basis for this should be, for example, quinones or azines – chemicals that are currently obtained from crude oil. “In the long term, you can see whether you can use renewable raw materials for this,” says Esser. The challenge here is to store as much charge as possible on as few molecules as possible. Because: “Ideally, you want a battery that weighs as little as possible and has a lot of storage capacity,” says Esser. This is one of the reasons why high porosity is important: it enables thicker electrodes, which lead to higher capacitance – the prerequisite for less material on the charge collector.

In order to see whether the porosity improves, methods are also to be established in NanOBatt with which the effect can actually be measured in interaction with other materials in batteries. “The methods commonly used do not work in this context,” says Esser. Finally, selected, redox-active nanohoops will be investigated as OEM in alternative battery cell configurations: in sodium, aluminium, magnesium and purely organic batteries.

Prof. Birgit Esser moved from the University of Freiburg to the University of Ulm in 2022. Before that she did research at the University of Bonn and at MIT in the USA. Esser studied and received his doctorate in Heidelberg. It is a member of the POLiS cluster of excellence (Post Lithium Storage Cluster of Excellence), where scientists develop new battery materials and technology concepts for efficient and sustainable storage of electrical energy. Esser is also a member of the CELEST research platform and associated group leader at the Helmholtz Institute in Ulm.

About the ERC Consolidator Grant

ERC Consolidator Grants are aimed at excellent researchers in the consolidation phase. The funding is primarily intended to support them in expanding their independent working group and increasing their international visibility. Typically, promising scientists from all disciplines apply seven to twelve years after their doctorate. An international jury, advised by external experts, decides on the quality of the applications submitted. The selected researchers receive up to two million euros for five years for their projects. In 2022, 2222 applications were submitted. Of these, 321 researchers from 21 countries were selected for an ERC Consolidator Grant. The only criterion is the scientific excellence of the researchers and the proposed project.

Further Information:

Prof. Birgit Esser, Institute for Organic Chemistry II and New Materials, Email: birgit.esser@uni-ulm.de, Group Website: www.esserlab.com

Text and Media Contact:

Christine Liebhardt

Photos: Elvira Eberhardt

May 24th, 2023

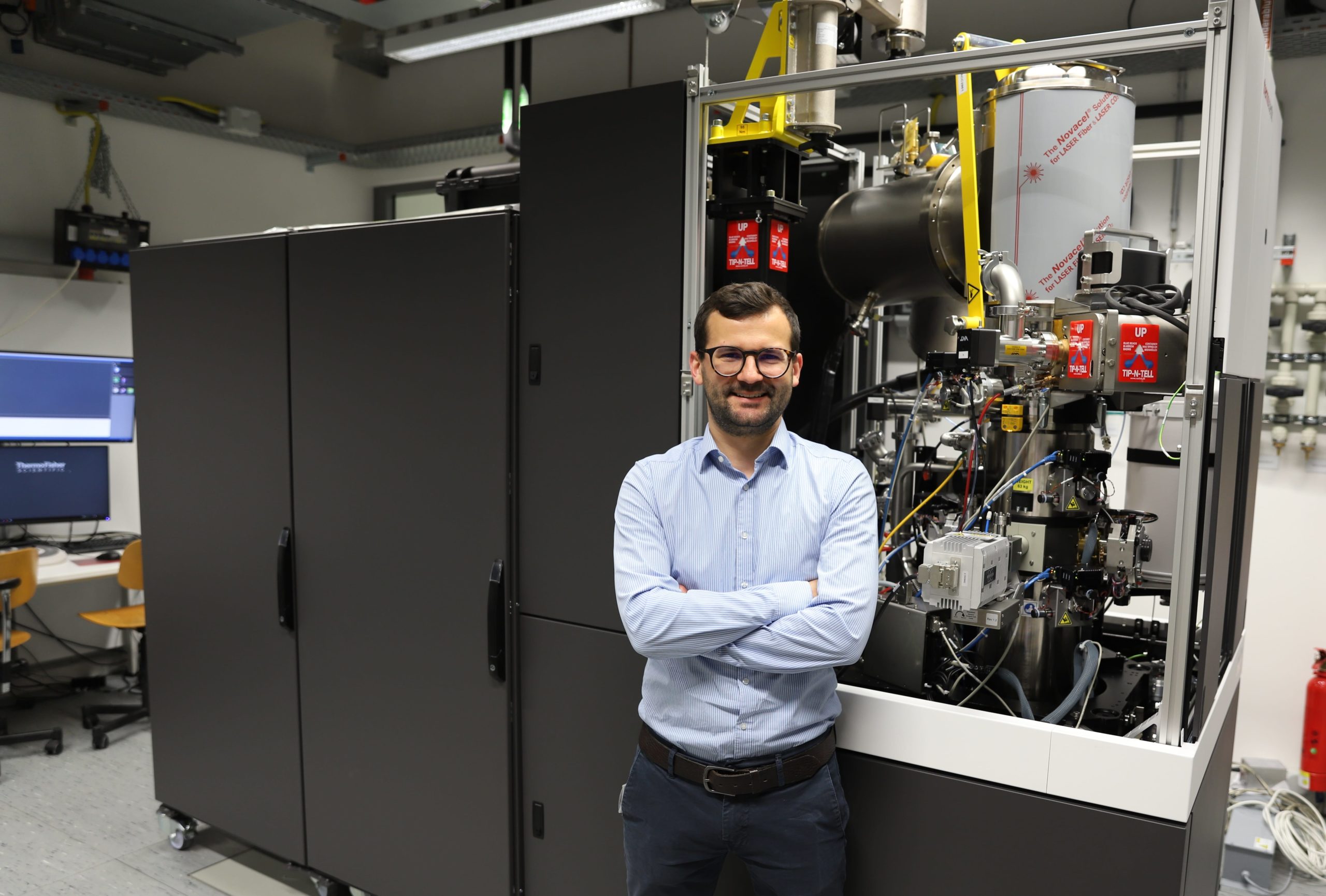

The HIU put its own transmission electron microscope (TEM) into operation in May. These microscopes are typically used to image thin samples at very high resolution. An electron beam with a high acceleration voltage is focused onto the sample from above. A detector placed under the sample registers the transmitted electrons. From this, conclusions can be drawn about the interaction between the electrons and the sample. The researchers receive very local information about the material.

Dr. Simon Fleischmann and his research group “Electrochemical Interfaces in Nanoconfinement” are responsible for the new device. We ask him for device details.

Dr. Fleischmann, can you give us some technical data on the TEM at the HIU?

Dr. Fleischmann: The device is equipped with a so-called “high brightness” Schottky field emission cathode with an acceleration voltage of 200 kV. The emitted electrons have an energy of 200,000 eV with an energy resolution of 1 eV, i.e. the electron energy deviates by at most 1 eV. This enables a very high resolution of just over 1 angstrom, which roughly corresponds to the bond length of atoms, to be achieved. The microscope is also equipped with two large area detectors for energy dispersive X-ray spectroscopy (EDX) and one detector for electron energy loss spectroscopy (EELS).

Photo: New Transmission Electron Microscope at HIU.

How does the device help you in research?

Dr. Fleischmann: Many of our conventional examination methods give us statistical information about the entirety of a sample, but we do not know what the sample looks like at a specific point, for example. In contrast to this, the TEM can be used to obtain structural and chemical information with an extremely high spatial resolution; one can, so to speak, look at the local environment of individual atoms at a particularly interesting point on the sample. It should also be emphasized that the TEM can not only “image”, but also diffraction and spectroscopy can be carried out with a similar spatial resolution.

Scientists at HIU put a ? transmission electron microscope (#TEM) into operation. For technical data, check our interview with @SFleischmann_ whose group will train ? researchers working with the device. @KITKarlsruhe @CELEST_18 @ClusterPolis @uni_ulm https://t.co/c7T8qBi4rd

— Helmholtz Institute Ulm ???? (@HelmholtzUlm) May 24, 2023

Which special materials (for which applications?) do you research with the TEM?

Dr. Fleischmann: We will mainly use the TEM for the investigation of novel electrode or solid electrolyte materials with unknown local structure as well as for interface characterization in electrochemical systems. A great deal of knowledge can be gained if, for example, one understands where and how ions or molecules are incorporated into a crystalline electrode material, or if one obtains highly localized information about interfaces and interphases that have arisen during electrochemical operation on electrode surfaces. So we are talking specifically about structure elucidation of materials with engineered crystal structure, e.g. my group’s “nanoconfinement materials”, solid electrolytes, and the exploration of interphases like the “solid electrolyte interphase” (SEI).

In these investigations, I would also like to highlight the specially purchased sample holders (so-called cryo holders), which “freeze” these highly sensitive and reactive samples with liquid nitrogen during the measurement. As a result, damage to the sample during measurement can be largely avoided and the original structure can be studied.

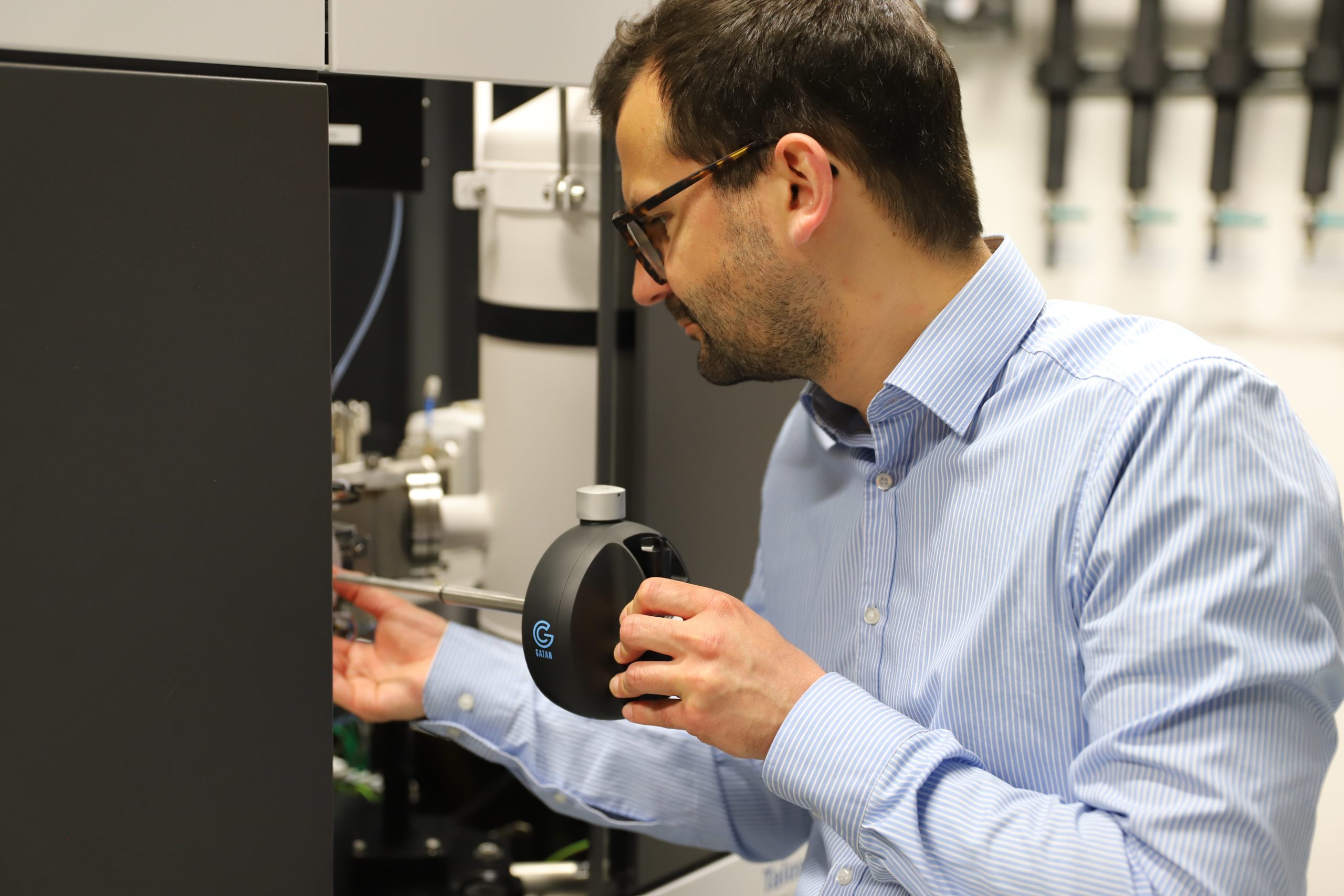

Photo: Inserting the TEM sample holder. This has a liquid nitrogen tank (“dewar”), which cools the sample during the measurement.

How important/complicated is the application software?

Dr. Fleischmann: The software is relatively complex precisely because of the diverse techniques that are possible with the TEM (“conventional” TEM, raster TEM, diffraction, spectroscopy, etc.). However, the user interface is designed quite intuitively and can be used well after instruction and training.

How much is a microscope worth? How long was the purchase planned? Dr. Fleischmann: With TEMs there are big price differences between the models, at the lower end it is a few hundred thousand euros, but at the upper end it can also be a few million euros. This mainly depends on the achievable measurement resolution, for which the “quality” of the emitted electrons (energy and energy range) and especially their focusing on the sample are decisive. The devices are also highly customizable in terms of equipment, you don’t buy them “off the peg”. That’s why I had to plan very carefully and weigh up which device with which equipment is suitable for our applications. Accordingly, the purchase took a lot of time, in total I was busy with the planning, ordering and assembly for about two years.

May 22nd, 2023

Dr Montaha Anjass, research group leader at the Helmholtz Institute Ulm and research associate in the POLiS Cluster of Excellence, was selected as a scholarship holder by the Christiane Nüsslein-Volhard Foundation. She receives a monthly grant of 500 euros for one year.

After completing her bachelor’s degree at Birzeit University and subsequently working as a teaching assistant, the native Palestinian emigrated to Ulm in 2013. Since July 2020, Dr. Anjass a research group at the Helmholtz Institute Ulm, which focuses on the development of novel nanostructured materials and their use in application areas of global socio-economic relevance such as energy conversion/storage or catalysis.

Congrats! ? Dr. Montaha Anjass, Group Leader at HIU & research associate at @ClusterPolis was selected for a scholarship by the Christiane Nüsslein-Volhard-Foundation. Keep up the great work! @KITKarlsruhe @uni_ulm @CELEST_18 @DLR_en https://t.co/T9m2QE3grq pic.twitter.com/CxrdXVl7iq

— Helmholtz Institute Ulm ???? (@HelmholtzUlm) May 22, 2023

The Christiane Nüsslein-Volhard Foundation was founded in 2004 and supports talented young female scientists with children to give them the freedom and mobility they need for a scientific career. Funds are made available to help relieve household chores and childcare.

Further Link:

https://cnv-stiftung.de/stipendiatinnen/stipendiatinnen-2023

April 27th, 2023

Once again, the Helmholtz Institute Ulm offered an individual program for the annual “Girls’Day” at the University of Ulm. This year, HIU organized the day together with the POLiS Cluster of Excellence. The day of action is intended to motivate girls and young women to take up technical and scientific professions. For the battery science institutes at Ulm University campus, it offers the opportunity to present career paths in typical “male professions” (chemistry, physics, mechanical engineering, etc.) to girls and young women.

Aufgepasst, Schülerinnen und Schüler: Noch bis 20. April könnt ihr euch für die Angebote des #GirlsDay und #BoysDay am 27. April an der #uulm, @UniklinikUlm und RKU anmelden. Alle Infos: https://t.co/4bxiCE9HyO *cl/Foto: Daniela Stang pic.twitter.com/lJVRjXw7W4

— Universität Ulm (@uni_ulm) April 17, 2023

Four schoolgirls visited the POLiS research laboratories at Lise-Meitner-Strasse in Ulm’s SciencePark. Doctoral student Monika Vogler showed the new MAP systems (“Materials Acceleration Platform”), in which battery materials are researched and optimized in high-throughput research using robotics.

The young people showed great interest and were able to ask Prof. Dr. Birgit Esser about career opportunities in battery research and science.

Weiterführende Links:

https://www.girls-day.de/