HIU-Newsletter

You a scientist yourself? A journalist, a political decision-maker or business representative? In our newsletters we compile the latest battery research news for you. Specially tailored to your personal area of interest.

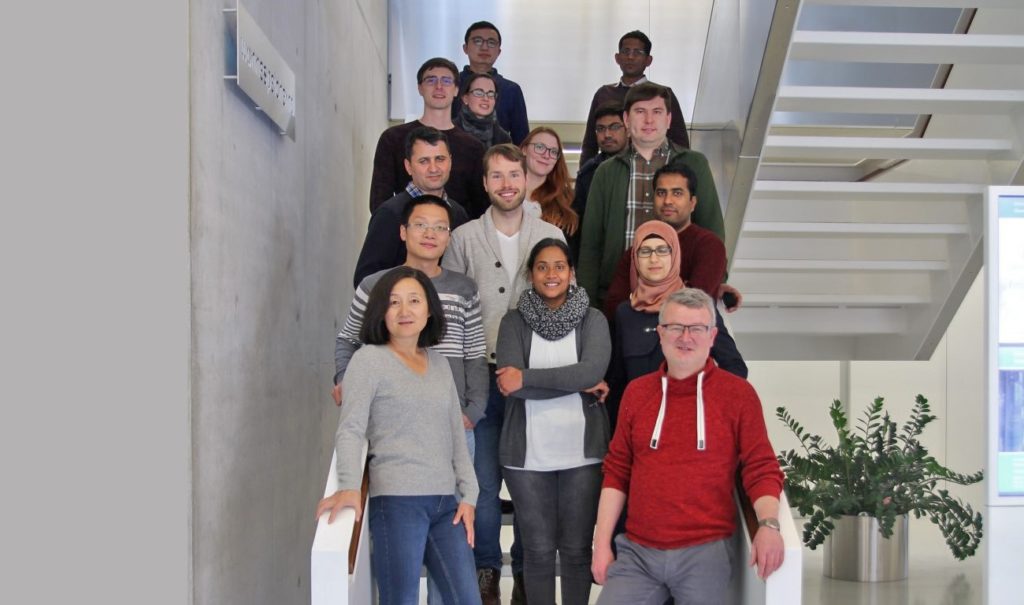

The HIU research group Solid State Chemistry is an interdisciplinary group in which chemists, physicists, and engineers are active. The focus of their research is on the battery systems to come after the lithium-ion ones, referred to simply as "batteries beyond lithium". Parallel to this work, new and alternative approaches are being developed to overcome the obstacles to lithium-free batteries.

Although lithium-ion batteries are widely used, their storage capacity is limited. In the future, battery systems with higher energy density will be needed, in particular for electromobility. These batteries will need the capacity to store more electrical energy at a lower weight. Lithium-free batteries will also be needed in the future that possess a markedly higher storage capacity and improved safety features.

This work should lay the cornerstone for innovative and more powerful batteries. One object of study is the potential of various battery materials to raise the energy density of today’s battery systems. Current examples of this are the fluoride-ion and chloride-ion batteries, both of which have the potential for significantly exceeding the storage capacity of the lithium-ion battery.

Another object of current research is the magnesium battery, which also exhibits a relatively high energy density. This research group is also involved in the development of active materials (e.g., electrode materials). One feature that has priority here is the issue of safety.

New anode and cathode materials made of nanocomposites are also being developed and tested in order to make electrochemical energy storage units more efficient.

In search of new concepts to build batteries with high energy densities, electrochemical cells based on metal fluorides may be promising.

We have demonstrated the first reversibly working battery cells based on fluoride shuttle. In secondary fluoride batteries, fluoride anion acts as charge transfer ion between a metal/ metal fluoride pair where it will react with metal or evolve from metal fluoride depending on the flow of current. The theoretical capacity can be several times higher than that of conventional Lithium Ion Batteries, depending on the combination of metal and metal Fluoride.

The Chloride Ion Battery (CIB) is a logical consequence of the development of the Fluoride Ion Battery. Also here, singly charged negative ions shuttle between cathode and anode where metal chlorides are either formed or reduced to the metal depending on whether the battery is charged or discharged.The group has demonstrated the proof-of-principle and built first cells of this kind. Ionic liquids have been used as elecrolytes at room temperature.

Magnesum as anode material has the potential advantage of a high theoretical volumetric capacity of 3832 mAh/cm3 (Lithium: 2062 mAh/cm3), its electrochemical potential is -2.37 V vs. NHE. Interestingly, Manesium does not form dendrites when electrodeposited and can therefore be used in metallic form, thus avoiding inert host materials like in the Lithium/Graphite system. Magnesium is environmentally benign, safe to handle and of low cost compared to lithium. A particular challenge is the development of an electrolyte for reversible Manesium shuttle. We have developed a non-nucleophilic electrolyte which is synthesized from standard chemicals, shows a high stripping/plating efficiency and has an unprecedented electrochemical stability window of 3.9 V and Coulombic efficiency of >99%. The electrolyte is compatible with a sulfur cathode and it opens the door to the development and application of new high voltage cathodes for Magnesium Batteries.

Using a sulfur/CMK-3 composite as cathode, Mg metal as anode and the designed electrolyte in tetraglyme or a binary solvent of glyme and PP14TFSI, the discharge performance and the cyclability of the batteries was considerably improved compared to the first report on Mg/S battery where an HMDS based electrolyte was used in THF solution. The electrochemical conversion of magnesium and sulfur via the formation of a series of intermediate polysulfide MgSx (2

A major issue in Metal-Sulfur Batteries is the formation of polysulfide intermediates during the transition from neutral S8 to Li2S and Li2S2 during discharge. The longer polysulfides are soluble in the electrolyte, which leads to gradual dissolution of the cathode, to self-discharge and a multistep voltage profile, due to different subsequent reactions.

By extensive XPS studies of the subsurface region we have shown now that a simple, coconut based active carbon with ultramicropores (ca. 0.6 nm diameter) does not allow infiltration of the large S8 rings, nor does it allow formation of soluble polysulfides. Rather, one direct transition from smaller sulfur species to Li sulfide and -disulfide is observed. No polysulfides have been found in the electrolyte and there is only one voltage plateau (M. Helen, M. Anji Reddy, T. Diemant, U. Golla-Schindler, R. J. Behm, and M. Fichtner (2015) submitted)

Tip Enhanced Raman Spectroscopy is an analytical tool which gives chemical and topographic information in the same time. It is a possibility to analyse surfaces with a resolution on nanometer scale. In battery research it is often not well-‐known, what is going on at surfaces and interfaces like the Solid Electrolyte Interface. The aim of this project is a better understanding of processes in these layers.

(images will be uploaded shortly)

Forscher aus fünf europäischen Forschungsinstituten (das HIU, die französische Alternative Energie- und Atomenergiekommission CEA, die Technische Universität Dänemark DTU, die schwedische Universität Uppsala und das slowenische Kemijski Institut NKI arbeiten gemeinsam im EU-finanzierten Projekt “LiRichFCC” Li-Ionen-Batterien zusammen. Auf der Grundlage eines neuen Konzeptes von Li-reichen Salzgesteinsstrukturen lassen sich Energiespeicherdichten über die bisher bekannten System hinaus erhöhen.

Das Projekt ist eine Kooperation zwischen dem HIU, dem DLR Stuttgart, der FhG-ISIT, CustomCells GmbH, der El-Cell GmbH und der Schaeffler AG mit dem Ziel, die Magnesium-Sulfur-Technologie auf Demonstrationsebene zu betreiben. Das technische Ziel ist die Herstellung und Prüfung von 20 Ah Mg-S Zellen.

Titel: “Novel in situ and in operando techniques for characterization of interfaces in electrochemical storage systems”. 8 Partner aus DK, UK, F, D mit assoziierten Partnern aus Korea and USA. Gemeinsam arbeiten die Projektpartner an internen und externen Grenzflächen von Batteriematerialien.

ProEco ist eine gemeinschafliches Projekt für Nanomaterialien für Anwendungen im Bereich der Energiespeicherung. Partner sind: DTU Energy Conversion, Aarhus University inano, Danish Technological Institute, Haldar Topsoe AS, Topsoe Fuel Cells, MPI für Kolloid und Grenzflächenforschung und KIT.

Das Projekt beschäftigt sich mit neuen Batteriematerialien basierend auf Magnesium-Nanomaterialien für angewandte, wieder aufladbare Batterien. Partner des Projekts sind: CNRS-ICMP France, KIT Germany, IFE Norway, RAS IPCP Russia, MSU Russia, St. Peterburg Univ. Russia, ISSP Russia

Das Projekthaus e-drive ist eine strategische Allianz mit Daimler zum Thema Elektromobilität bzw. Elektroantriebe.

Die Allianz Projekthaus e-drive

CUSTOMCELLS® is one of the world’s leading companies in the development of special lithium-ion battery cells. CUSTOMCELLS® – Made in Germany – develops and produces application-specific battery cells from prototypes to small and medium series. On the basis of flexible manufacturing concepts and state-of-the-art research and production facilities, CUSTOMCELLS® guarantees high-tech solutions for special applications and – depending on the customer requirement profile – tailor-made development and production of electrodes, electrolytes, battery cells and battery modules. With access to 14 industrialized electrode technologies, over 250 raw materials in stock and a production facility equipped with state-of-the-art electrode and cell manufacturing machines, CUSTOMCELLS® is one of the leading manufacturers of customized battery cells.

In search of new concepts to build batteries with high energy densities, electrochemical cells based on metal fluorides may be promising.

We have demonstrated the first reversibly working battery cells based on fluoride shuttle. In secondary fluoride batteries, fluoride anion acts as charge transfer ion between a metal/ metal fluoride pair where it will react with metal or evolve from metal fluoride depending on the flow of current. The theoretical capacity can be several times higher than that of conventional Lithium Ion Batteries, depending on the combination of metal and metal Fluoride.

The Chloride Ion Battery (CIB) is a logical consequence of the development of the Fluoride Ion Battery. Also here, singly charged negative ions shuttle between cathode and anode where metal chlorides are either formed or reduced to the metal depending on whether the battery is charged or discharged.The group has demonstrated the proof-of-principle and built first cells of this kind. Ionic liquids have been used as elecrolytes at room temperature.

Magnesum as anode material has the potential advantage of a high theoretical volumetric capacity of 3832 mAh/cm3 (Lithium: 2062 mAh/cm3), its electrochemical potential is -2.37 V vs. NHE. Interestingly, Manesium does not form dendrites when electrodeposited and can therefore be used in metallic form, thus avoiding inert host materials like in the Lithium/Graphite system. Magnesium is environmentally benign, safe to handle and of low cost compared to lithium. A particular challenge is the development of an electrolyte for reversible Manesium shuttle. We have developed a non-nucleophilic electrolyte which is synthesized from standard chemicals, shows a high stripping/plating efficiency and has an unprecedented electrochemical stability window of 3.9 V and Coulombic efficiency of >99%. The electrolyte is compatible with a sulfur cathode and it opens the door to the development and application of new high voltage cathodes for Magnesium Batteries.

Using a sulfur/CMK-3 composite as cathode, Mg metal as anode and the designed electrolyte in tetraglyme or a binary solvent of glyme and PP14TFSI, the discharge performance and the cyclability of the batteries was considerably improved compared to the first report on Mg/S battery where an HMDS based electrolyte was used in THF solution. The electrochemical conversion of magnesium and sulfur via the formation of a series of intermediate polysulfide MgSx (2

A major issue in Metal-Sulfur Batteries is the formation of polysulfide intermediates during the transition from neutral S8 to Li2S and Li2S2 during discharge. The longer polysulfides are soluble in the electrolyte, which leads to gradual dissolution of the cathode, to self-discharge and a multistep voltage profile, due to different subsequent reactions.

By extensive XPS studies of the subsurface region we have shown now that a simple, coconut based active carbon with ultramicropores (ca. 0.6 nm diameter) does not allow infiltration of the large S8 rings, nor does it allow formation of soluble polysulfides. Rather, one direct transition from smaller sulfur species to Li sulfide and -disulfide is observed. No polysulfides have been found in the electrolyte and there is only one voltage plateau (M. Helen, M. Anji Reddy, T. Diemant, U. Golla-Schindler, R. J. Behm, and M. Fichtner (2015) submitted)

Tip Enhanced Raman Spectroscopy is an analytical tool which gives chemical and topographic information in the same time. It is a possibility to analyse surfaces with a resolution on nanometer scale. In battery research it is often not well-‐known, what is going on at surfaces and interfaces like the Solid Electrolyte Interface. The aim of this project is a better understanding of processes in these layers.

(images will be uploaded shortly)

Forscher aus fünf europäischen Forschungsinstituten (das HIU, die französische Alternative Energie- und Atomenergiekommission CEA, die Technische Universität Dänemark DTU, die schwedische Universität Uppsala und das slowenische Kemijski Institut NKI arbeiten gemeinsam im EU-finanzierten Projekt “LiRichFCC” Li-Ionen-Batterien zusammen. Auf der Grundlage eines neuen Konzeptes von Li-reichen Salzgesteinsstrukturen lassen sich Energiespeicherdichten über die bisher bekannten System hinaus erhöhen.

Das Projekt ist eine Kooperation zwischen dem HIU, dem DLR Stuttgart, der FhG-ISIT, CustomCells GmbH, der El-Cell GmbH und der Schaeffler AG mit dem Ziel, die Magnesium-Sulfur-Technologie auf Demonstrationsebene zu betreiben. Das technische Ziel ist die Herstellung und Prüfung von 20 Ah Mg-S Zellen.

Titel: “Novel in situ and in operando techniques for characterization of interfaces in electrochemical storage systems”. 8 Partner aus DK, UK, F, D mit assoziierten Partnern aus Korea and USA. Gemeinsam arbeiten die Projektpartner an internen und externen Grenzflächen von Batteriematerialien.

ProEco ist eine gemeinschafliches Projekt für Nanomaterialien für Anwendungen im Bereich der Energiespeicherung. Partner sind: DTU Energy Conversion, Aarhus University inano, Danish Technological Institute, Haldar Topsoe AS, Topsoe Fuel Cells, MPI für Kolloid und Grenzflächenforschung und KIT.

Das Projekt beschäftigt sich mit neuen Batteriematerialien basierend auf Magnesium-Nanomaterialien für angewandte, wieder aufladbare Batterien. Partner des Projekts sind: CNRS-ICMP France, KIT Germany, IFE Norway, RAS IPCP Russia, MSU Russia, St. Peterburg Univ. Russia, ISSP Russia

Das Projekthaus e-drive ist eine strategische Allianz mit Daimler zum Thema Elektromobilität bzw. Elektroantriebe.

Die Allianz Projekthaus e-drive

CUSTOMCELLS® is one of the world’s leading companies in the development of special lithium-ion battery cells. CUSTOMCELLS® – Made in Germany – develops and produces application-specific battery cells from prototypes to small and medium series. On the basis of flexible manufacturing concepts and state-of-the-art research and production facilities, CUSTOMCELLS® guarantees high-tech solutions for special applications and – depending on the customer requirement profile – tailor-made development and production of electrodes, electrolytes, battery cells and battery modules. With access to 14 industrialized electrode technologies, over 250 raw materials in stock and a production facility equipped with state-of-the-art electrode and cell manufacturing machines, CUSTOMCELLS® is one of the leading manufacturers of customized battery cells.

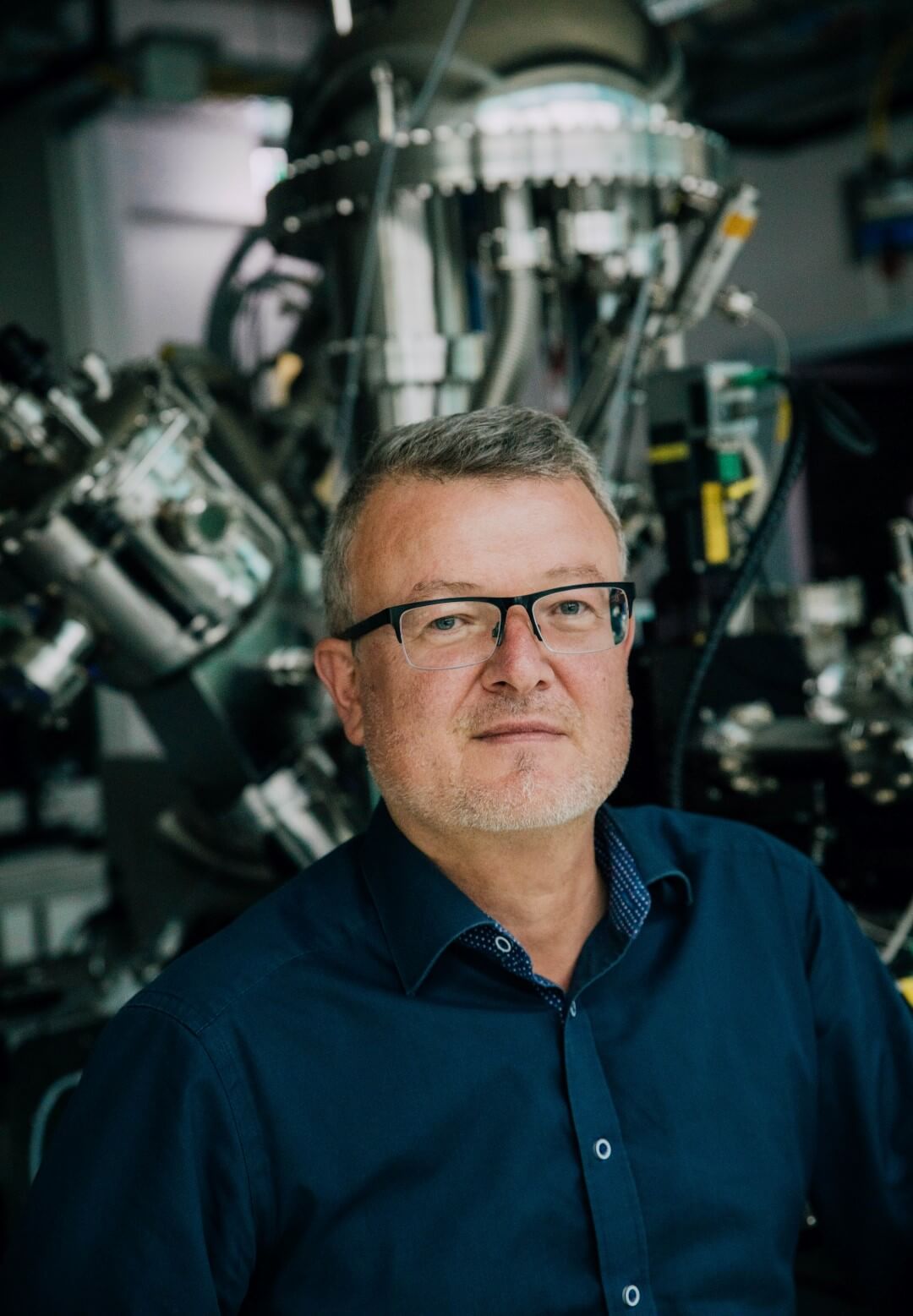

Prof. Dr. Maximilian Fichtner Solid-State Chemistry Tel: +49 (0731) 50 34201 Mail: maximilian.fichtner(at)kit.edu

Prof. Dr. Maximilian Fichtner Solid-State Chemistry Tel: +49 (0731) 50 34201 Mail: maximilian.fichtner(at)kit.edu Katja Vetter

Office Prof. Dr Maximilian Fichtner

Tel: +49 (0731) 50 34020

Mail: katja.vetter@kit.edu

You a scientist yourself? A journalist, a political decision-maker or business representative? In our newsletters we compile the latest battery research news for you. Specially tailored to your personal area of interest.

Helmholtz Institute Ulm Electrochemical energy storage (HIU)

Helmholtzstraße 11

89081 Ulm

Germany

Tel.: +49 0731 5034001

Fax: +49 (0731) 50 34009