November 3rd, 2021

On November 3rd, 2021, the recently re-elected member of the Bundestag Ronja Kemmer (CDU) was a guest at the Helmholtz Institute Ulm. For the CDU/CSU parliamentary group, Kemmer used to be both, a full member of the committee for “Education, Research and Technology Assessment” and a deputy member of the committee for “Economy and Energy”.

The energy transition and energy storage are becoming more and more central to politics. The discussion about sustainable energy generation and efficient security of supply often leads to the question: Where will innovative energy storage devices be used in the future and what will they have to do? On November 3rd, some HIU scientists discussed what such a future could look like with the member of the Bundestag from Ulm. After a few occasions, Kemmer came to the HIU for another informal exchange about current progress in battery research.

The exchange was scientifically accompanied by Prof. Dr. Maximilian Fichtner (Director of the Helmholtz Institute Ulm), who provided an overview of current research results and activities of HIU, the Cluster of Excellence POLiS and the CELEST research platform. Also invited were Prof. Dr. Helge Stein (HIU/KIT), PD Dr. Birger Horstmann (HIU/DLR), Dr. Wohlfahrt-Mehrens (HIU/ZSW) and Prof. Dr. Axel Groß (HIU / Ulm University).

November 1st, 2020

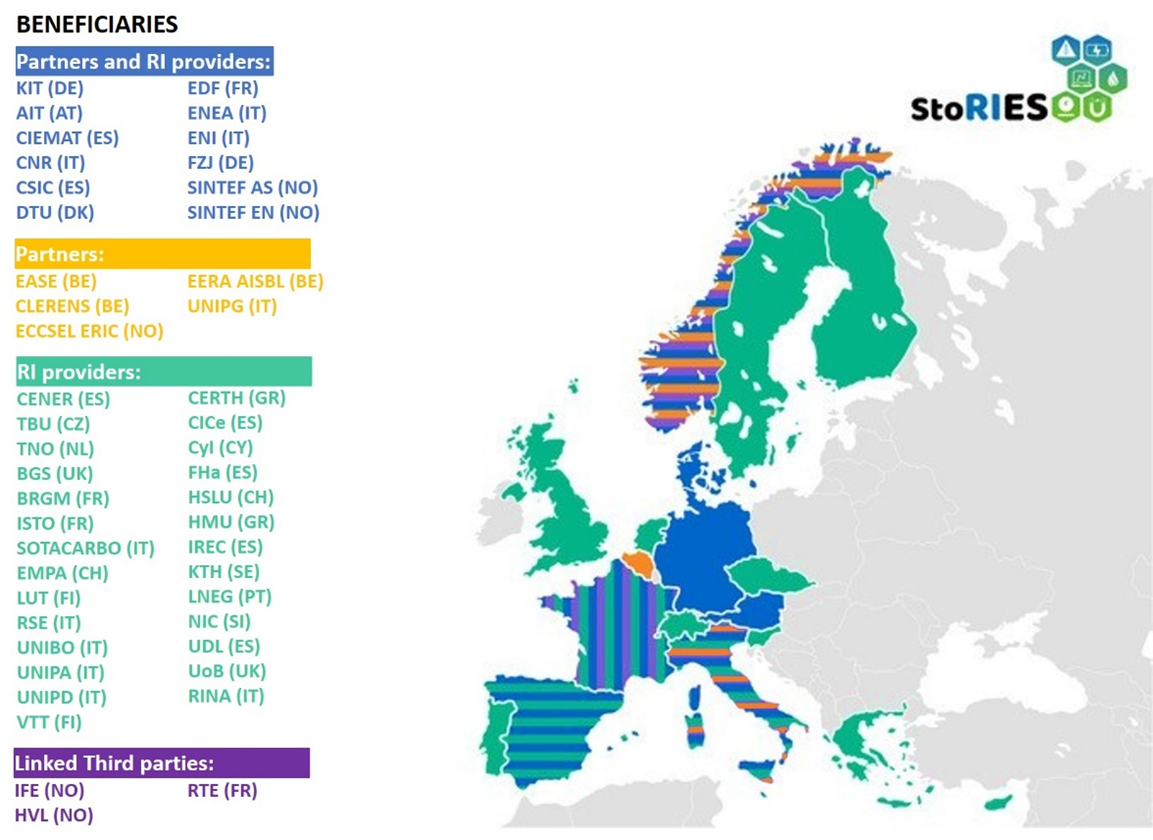

StoRIES (Storage Research Infrastructure Eco-System), a €7 million worth H2020 project, coordinated by Helmholtz Institute Ulm (HIU) and Karlsruhe Institute of Technology (KIT), kicked-off 1st November 2021. StoRIES will address the “European Green Deal” objective to ensure that the EU achieves climate neutrality by 2050 focusing on the energy sector, which is to be transformed with a consistent shift towards electricity generation based on renewable energies. In particular, StoRIES will work on the development of innovative energy storage methods and on defining the current and future needs of the energy systems regarding the energy storage.

The StoRIES consortium includes a total of 17 partners, which are technology institutes, universities and industry representatives, and 31 associated participants from 17 countries. All involved entities have an extensive background in energy storage technologies (electrochemical, chemical, thermal, mechanical and superconducting magnetic storage). Two of them, the European Energy Research Alliance (EERA) and the European Association for Energy Storage (EASE), are the largest research and industry associations dealing with energy storage in Europe and they will form the core of the new ecosystem.

Welcome! “Storage Research Infrastructure Eco-System” (StoRies) – ?????????⚡️? With Europe’s “Green Deal”, a new European research consortium for Energy Storage starts at HIU/KIT. https://t.co/zGGboRWZk8

— Helmholtz Institute Ulm ?? (@HelmholtzUlm) September 16, 2021

The main task of StoRIES is to bring together scientific institutions, such as technology institutes and universities, with industrial partners in order to jointly develop storage solutions for new technology and energy markets. According to the project coordinator, Stefano Passerini, the focus is on transdisciplinary cooperation: “The pooling of know-how within science and industry opens up synergies that are often underestimated. At the same time, we would like to make energy storage research more holistic and add socio-technical and ecological aspects. With the European Green Deal until 2050, politics gives us an immense homework that we can only manage together.”

StoRIES will offer training for industry and research institutions as well as courses for young scientists developing the innovative hybrid solutions of the future. The purely technical training around energy storage systems is to be complemented by the ecological, legal, economic and social aspects surrounding energy storage systems. StoRIES intends to break down the barriers between research fields that today often operate in a very closed manner in order to enable mutual understanding and cooperation. The ecosystem of experts from different energy, social , and economic research, industry and consumer representatives is intended to outlast StoRIES and enable an effective and sustainable exchange on the topic of energy storage.

The most important technological goal of StoRIES is the development of future energy storage systems of all kinds. Through shared access to 64 world-class research infrastructures and services gathered in StoRIES, the aim is to drive research and innovation. Energy storage is essential for the energy transition; but no single storage technology available today that can meet this challenge on its own. Rather, a combination of different energy storage technologies is required to deliver the expected performance in terms of capacity, flexibility and sustainability. The StoRIES consortium brings together all the main areas of energy storage research that will focus on the hybrid solutions idea.

To optimise hybrid energy storage solutions, StoRIES will focus on improving material properties for current and future applications. A system of modern supercomputers, automation technologies and the use of artificial intelligence (AI) will enable targeted material development for innovative energy storage devices. Such joint platforms will make the energy storage research more efficient, sustainable and cost-effective, but the goal is also to shorten the development times for new technologies by a factor of 10, to bring new innovations to market faster, so that renewable energy technologies also become competitive more quickly.

In StoRIES, new materials, devices and technologies will be analysed with respect to the socio-technical and ecological aspects. StoRIES will promote a fair transition to carbon neutrality by supporting the product development process, especially in the early stages of design, and aiming to optimise the use of raw materials and increase recyclability. This will help to reduce environmental impacts and maximise social benefits. Issues of public approval, regulatory frameworks and economics for the application of the new solutions will be analysed, the ways to unlock the potential of energy storage will be explored and the bottlenecks that prevent this will be identified.

Further Information

https://www.eera-energystorage.eu/stories.html

October 01, 2021

Since October 1, 2021, Prof. Dr. Maximilian Fichtner once again takes the role of Executive Director at Helmholtz Institute Ulm (HIU). The Board of Directors of the institute is again changing its head after his predecessor Prof. Dr. Stefano Passerini has held the office since October 2018. According to the statutes, a rotation is planned every three years. Prof. Fichtner begins his second term of office as executive director. In 2015 he replaced founding director Prof. Horst Hahn in this position.

Prof. Dr. Maximilian Fichtner is our new 2021 (and former 2015) Executive Director of HIU. ?? Follow the link for his view on our institute’s future. #battery #science @KITKarlsruhe @CELEST_18 @2030Battery @ClusterPolis https://t.co/nlpClPq3DN

— Helmholtz Institute Ulm ?? (@HelmholtzUlm) October 11, 2021

Prof. Fichtner, everyone is currently talking about electromobility and battery research. Which research topics relating to electromobility will be the focus of the next three years at the HIU?

Prof. Dr. Fichtner: “The main focus of the HIU is certainly on the topics – “Further” (more storage capacity”),”Faster” (faster loading) and “More sustainable” (without the use of critical raw materials). With regard to the latter point in particular, we are now one of the leading institutions in Europe. Winning the POLiS Cluster of Excellence gave us exceptional opportunities to research batteries that do not use lithium or heavy metals.”

What challenges are you currently facing at the HIU? As at every research institution, there are certainly very own visions, but also problems.

Prof. Dr. Fichtner: “We have to master the challenge that the HIU faces constantly rising costs with the same basic funding. Furthermore, we are slowly getting space problems in the HIU building and – despite very successful third-party funding so far – we cannot continue to grow at the moment.

In general, opportunities arise from the fact that we have developed into one of the most important research institutes in Europe over the past 10 years. This makes it easier to participate in important research projects. Our expertise is unique and we address the most important and pressing questions in our research fields.”

Since October 1st, 2021 you have been “Executive Director” at the HIU again – for the second time. Where do you see your personal role?

Prof. Dr. Fichtner: “My first time as executive director was marked by the strengthening of the Ulm-Karlsruhe association. To this end, we founded CELEST, acquired the POLiS Cluster of Excellence and, as an association, have now reached a central position in the major European initiative BATTERY 2030+.

We have also made efforts to strengthen the HIU by attracting excellent young research groups and to make it better known overall. This was only feasible through the joint effort of all colleagues and was very successful in the end.

It remains to be seen what the new director’s time will bring. We have to keep the HIU stable and lead it into a successful and exciting future with a sustainable program. There are still exciting topics ahead of us.”

What did you particularly appreciate about your predecessor Prof. Dr. Stefano Passerini?

Prof. Dr. Fichtner: “Prof. Passerini is an excellent colleague and scientist of high international stature. He can regularly be found in the list of the most cited scientists in our field. His word carries weight in the community; and this is how he succeeded in taking on an important coordinating role within the framework of the European Energy Alliance (EERA). This contributes a lot to the visibility of our institute.”

A word to the young scientists. One important focus at the HIU is increasingly focusing on the next generation: Which researchers are you looking for at the HIU in the future?

Prof. Dr. Fichtner: “I think it’s scientists who want to make a difference. Scientists who know that they can benefit from the excellent scientific environment and who want to have their time at the HIU clearly on the credit side of their resume. Some come to fill a clearly defined task in a joint project with life, some come with their own ideas. After testing, we give you the opportunity to realize this with us. In this way, we have already started several junior research groups and we are pleased about the high visibility that these groups have already achieved.”

Thank you for the interview, Prof. Fichtner.

In the seminar at the Helmholtz Institute Ulm (HIU), outstanding international battery researchers share their scientific findings and technological inventions with Ulm scientists and students. The seminar takes place every Tuesday at 2:00 p.m. during the lecture period.

29.09.2021

Prof. Dr. Ehrenfried Zschech

deepXscan GmbH, Dresden, Germany

03.11.2021

Prof. Dr. Patrik Johansson

Chalmers University of Technology, Göteborg Sweden & Alistore-ERI, FR CNRS 3104, Amiens, France

17.11.2021

Prof. Dr. Elie Paillard

Politecnico di Milano, Milano, Italy

01.12.2021

Dr. Simon Fleischmann

Helmholtz Institute Ulm (HIU)

08.12.2021

Dr. Tobias Placke

MEET Battery Research Center, Institute of Physical Chemistry, University of Münster, Germany

15.12.2021

T.T.-Prof. Dr.-Ing. Helge S. Stein

Karlsruhe Institute of Technology (KIT), Helmholtz Institute Ulm (HIU)

2022

12.01.2022

Prof. Dr. Jürgen Janek

Justus Liebig University Giessen (JLU) & Karlsruhe Institute of Technology (KIT), Germany

19.01.2022

Prof. Dr. Ivana Hasa

WMG, The University of Warwick, Coventry, United Kingdom

02.02.2022

Prof. Dr. Thierry Brousse

Université de Nantes, CNRS, Institut des Matériaux de Nantes Jean Rouxel, IMN & RS2E, CNRS 3459, Amiens, France

09.02.2022

Dr. Maria Assunta Navarra

Sapienza University of Rome, Italy

16.02.2022

Prof. Dr. Francesca Soavi

Department of Chemistry “Giacomo Ciamician”, Alma Mater Studiorum University of Bologna, Italy. Bettery srl, Massafra (TA), Italy

11.03.2022

Dr. Michael Mercer

Chemistry Department, Lancaster University, United Kingdom

22.03.2022

Prof. Dr. Brett L. Lucht

Department of Chemistry, The University of Rhode Island, USA

28. September 2021

Within the ALANO Project, Industry and Science Develop Innovative Concepts for Accumulators with a Lithium-metal Anode

Solid-state batteries may push electric mobility. Within the new application-oriented ALANO project coordinated by BMW AG, partners from industry and science study lithium batteries of the next generation: A lithium metal anode and a solid electrolyte ensure high safety and enhance energy density on cell level, thus increasing the range of electric cars. The Helmholtz Institute Ulm (HIU) is significantly involved in the project funded by the Federal Ministry of Research.

Forschung für sichere #Feststoffbatterien: Im Projekt ALANO entwickeln Industrie und Wissenschaft innovative Konzepte für Akkus mit Lithiummetall-Anode – Forschende des KIT untersuchen elektrochemische Aspekte. https://t.co/DwcyPuSBY8 pic.twitter.com/irnw40Kqih

— KIT Karlsruhe (@KITKarlsruhe) September 27, 2021

Light and powerful, inexpensive and safe – accumulators for electric cars have to meet several criteria. For some time now, battery researchers and automotive manufacturers have therefore focused on solid-state batteries. In such batteries, both electrodes and the electrolyte are made of solid materials. The solid electrolyte in particular promises to enhance safety: It is hardly inflammable and cannot leak. The new collaboration project ALANO (stands for: Alternative Anode Concepts for Safe Solid-state Batteries) deals with lithium batteries of the next generation and focuses on the lithium metal anode as the central component. ALANO is aimed at enhancing energy density of a solid-state battery at high safety.

Higher Energy Density – Longer Range

“Use of lithium metal as anode material may considerably enhance energy density on cell level and, thus, increase the range of electric cars,” says Professor Stefano Passerini, Director of the Helmholtz Institute Ulm (HIU), one of the partners of ALANO, and Head of the Electrochemistry for Batteries Group. Within the ALANO project, partners from research and industry evaluate various innovative lithium metal-based anode concepts for solid-state batteries in order to optimize reactivity, safety, and performance of the anode and to integrate the latter in a robust cell unit of high energy density. Combination with a solid electrolyte is of decisive importance. Contrary to conventional liquid electrolytes that strongly react with lithium metal, solid electrolytes are less reactive and, hence, enable formation of kinetically stable interfaces. This promises to result in several advantages: “First, safety will be improved considerably, as the cells will not contain any liquid and easily inflammable substances,” says Dr. Dominic Bresser, Head of the Electrochemical Energy Storage Materials Group of HIU. “Second, robustness of the cells is increased, which facilitates handling, cooling, and system integration.” In this way, costs on the cell, module, and system levels will be reduced. At the same time, durability of the cells is increased, thus improving its sustainability.

Research and Development along the Chain of Values Added

The ALANO project covers the entire chain of values added of solid-state batteries with a lithium metal anode: From the selection of materials to the manufacture of components, to producing cells, to battery scaling for use in vehicles and other applications, to recycling. Hence, circular economy aspects will also be taken into account. Partners from industry and research collaborate across branches and disciplines in the ALANO project.

The consortium is coordinated by BMW AG. Among the other industry partners are Applied Materials GmbH, ARLANXEO GmbH, DAIKIN Chemical Europe GmbH, RENA Technologies GmbH, and VARTA Microbattery GmbH. Research partners include HIU, Fraunhofer Institute for Manufacturing Technology and Advanced Materials IFAM, Fraunhofer Institute for Surface Engineering and Thin Films IST, Forschungszentrum Jülich (FZJ), Electrochemical Energy Technology Battery Research Center (MEET) at the University of Münster, Center for Solar Energy and Hydrogen Research Baden-Württemberg (ZSW), and Gießen University. BASF SE is an associated project partner. ALANO will start in September 2021 and is scheduled for a duration of three years. The Federal Ministry of Education and Research (BMBF) will fund ALANO under the “Battery 2020 Transfer” program (battery materials for future electromobile, stationary, and other industrially relevant uses).

Further information

https://www.kit.edu/kit/pi_2021_085_forschung-fur-sichere-feststoffbatterien.php

https://www.maschinenmarkt.vogel.de/das-sind-die-feststoffbatterien-der-naechsten-generation-a-1059372/

September 18th, 2021

To get to the official subpage of the “Open Battery Day 2021” at HIU, please follow this link (Link).

September 17th, 2021

To get to the official subpage of HIU’s “10th Anniversary Celebration“, please follow this link (Link).

September 16, 2021

The member states of the European Union (EU) plan to achieve climate neutrality by 2050. This will not only require extended use of renewable energy sources, but also investments in energy storage systems. StoRIES, a new European research consortium, has now been established to accelerate their development. It is coordinated by Helmholtz Institute Ulm (HIU) that was founded by Karlsruhe Institute of Technology (KIT) and Ulm University.

Welcome! “Storage Research Infrastructure Eco-System” (StoRies) – ?????????⚡️? With Europe’s “Green Deal”, a new European research consortium for Energy Storage starts at HIU/KIT. https://t.co/zGGboRWZk8

— Helmholtz Institute Ulm ?? (@HelmholtzUlm) September 16, 2021

In December 2019, the European Commission presented the “European Green Deal” to reach its climate goals. The focus lies on the energy sector that is planned to be transformed to enable power production from renewable energy sources. However, this alone will not be sufficient, says Professor Stefano Passerini, Director of HIU: “To use the fluctuating renewable energy sources of wind and solar power on a large scale, we will need the corresponding energy storage systems.” For this reason, the “Green Deal” also includes coordinated research and development work in Europe, among others in the new research consortium StoRIES (Storage Research Infrastructure Eco-System). It will enable researchers from all over Europe who have specialized in different fields to pool their knowledge and work together on hybrid energy storage technologies in close cooperation with industry. “We want to accelerate development of new, innovative, and mature storage solutions and have created a joint ecosystem for this purpose,” Passerini says. And the coordinator of StoRIES continues: “Pooling of know-how opens up often underestimated synergies. The “European Green Deal” presents us challenging homework that can only be done together.” On November 1, 2021, work will start officially.

Accelerated Development with Smart Methods

The most important technical goal of StoRIES is the development of future energy storage systems of all kinds. The research consortium will mainly focus on hybrid storage systems. “We will need powerful, persistent, sustainable, and inexpensive solutions,” Dr. Myriam Gil Bardají says. The science manager coordinates the activities of the European Energy Research Alliance (EERA) at KIT and was involved in the establishment of StoRIES. “At the moment, however, no energy storage technology is sufficiently flexible to meet all these criteria. It will therefore be necessary to combine technologies. In this way, we will benefit from advantages and compensate drawbacks.”

Joint access to first-class research infrastructures and services will remove research obstacles and push innovation. Research is aimed at improving material properties for current and future applications and optimizing hybrid energy storage systems. “We also work on reducing development times for new technologies by a factor of ten,” says Dr. Holger Ihssen from the Brussels Office of the Helmholtz Association that supported the launch of the new research consortium. “We also want to accelerate commercialization of new innovations for renewable energy technologies to become competitive much faster.” This will be achieved by the use of modern supercomputers, automation technologies, and artificial intelligence (AI) for specific development of materials suited for energy storage systems. In addition, StoRIES will analyze sociotechnical and ecological aspects. “To reduce environmental impacts, the new storage technologies will be optimized in terms of resource consumption and recyclability from the very beginning,” Ihssen points out.

Transdisciplinary Education of Tomorrow’s Specialists

The new alliance of research and industry will also assume responsibility for the education of the new generation of researchers, engineers, and specialists. Apart from courses for companies, universities, and young scientists, training on ecological, legal, economic, and social aspects of energy storage systems will be offered. “For the energy transition to be successful, we will not only need adequate technologies, but also an understanding of non-technical aspects, such as public approval, legal framework conditions, and economic efficiency,” says Dr. Olga Suminńska-Ebersoldt, science manager at HIU and one of the initiators of StoRIES. “Mutual understanding across the borders of the often separate research groups will enable close collaboration.” Through education of tomorrow’s specialists, the transdisciplinary approach to the development of energy storage technologies will persist even after the termination of StoRIES.

StoRIES: A Unique Ecosystem for Energy Storage Research

The new consortium of institutes of technology, universities, and industrial companies comprises 17 partner institutions and 31 associated partners from 17 countries, who have vast expertise on energy storage technologies (electrochemical, chemical, thermal, mechanical, and superconducting magnetic storage systems). Members of the European Energy Research Alliance (EERA) and the European Association for Storage of Energy (EASE) form the core of the new ecosystem. The European Commission funds StoRIES with about EUR 7 million for initially four years under the Horizon 2020 program.

Further information

https://www.eera-energystorage.eu/stories.html

September 15th/16th, 2021

To get to the official subpage of the “Biennial Meeting 2021” at HIU, please follow this link (Link).

September 1st, 2021

The Carus Medal goes to KIT scientist: Dominic Bresser receives the Leopoldina award for his significant contributions to battery research

The Leopoldina, the National Academy of Sciences, honors the research of HIU’s chemist Dominic Bresser from the Karlsruhe Institute of Technology (KIT) with this year’s Carus Medal for the outstanding research work in his field. The Carus Medal honors significant scientific discoveries and research achievements by younger researchers. The award will be presented to the scientist in Halle (Saale) at a ceremonial opening of the Leopoldina annual meeting in compliance with the Corona rules on Friday, September 24, 2021.

Congratulations, Dominic Bresser! ??️ The National Academy of Sciences @Leopoldina honored our HIU colleague, Head of #Battery Research Group Electrochemical Energy Storage Materials, with the Carus medal. https://t.co/IdEOFATtzh https://t.co/D77T8Y13E5

— Helmholtz Institute Ulm ?? (@HelmholtzUlm) September 6, 2021

Dominic Bresser and his research group Electrochemical Energy Storage Materials, deals with energy storage in batteries. Improving them and making them more sustainable is important for electromobility and other aspects relevant to the energy transition. The scientist researches alternative electrode materials and electrolyte systems for lithium-based batteries and related technologies. He contributed significantly to various innovations such as two new classes of anode materials and an electrolyte system based on ionic organic liquid crystals. His work helps to expand the range of storage technologies.

Further information

https://www.kit.edu/kit/29640.php

https://www.leopoldina.org/presse-1/pressemitteilungen/pressemitteilung/press/2812/